Bar Tond tal-Azzar tal-Karbonju Rrumblat bis-Sħana GB Bar Tond Standard 20# 45# Prezz tal-Bar Tond

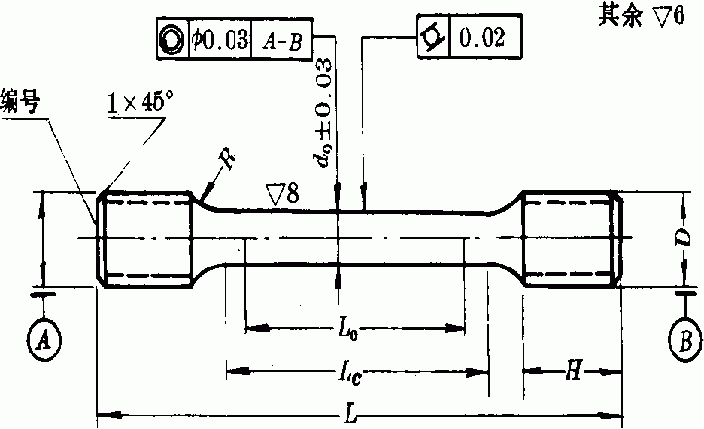

Id-dettalji ta'bar tond tal-azzar bi struttura tal-karbonjutipikament jinkludu d-dimensjonijiet, bħad-dijametru u t-tul, kif ukoll il-grad jew l-ispeċifikazzjoni speċifika. Vireg tondi tal-azzar tal-karbonju, bħal AISI 1018, 1045, u 1144, huma kkaratterizzati mill-proprjetajiet u l-kompożizzjoni kimika tagħhom. Saħħa tajba, makkinabbiltà, u weldjabbiltà jagħmlu dawn il-prodotti adattati għall-magni, il-manifattura, u l-applikazzjonijiet tal-bini. Konsiderazzjonijiet oħra jistgħu jkunu l-finitura tal-wiċċ, it-tolleranzi dimensjonali u l-istandards eż. ASTM jew SAE.

PROĊESS TA' PRODUZZJONI TAL-PRODOTT

1.Tħejjija tal-materja prima

Għażla: Agħżel biss azzar ta’ kwalità tajba mingħajr skala, xquq u impuritajiet oħra.

Qtugħ: Maqtugħ għat-tul u d-dijametru bit-truf ħielsa minn tbajja’ jew difetti oħra.

2. Raffinar

Purifikazzjoni: it-tneħħija ta' kontaminazzjonijiet b'diversi mezzi li jinkludu separazzjoni manjetika u ġbir bl-idejn.

Tisħin minn qabel: Ġib għat-temperatura tal-ipproċessar.

Dekarbonizzazzjoni: Trattament b'temperatura għolja għat-tneħħija tal-karbonju, il-kubrit u l-fosfru u għall-aġġustament tal-kompożizzjoni.

3. Ipproċessar u Iffurmar

Preformazzjoni: L-azzar raffinat jiġi preformat f'vireg.

Trattament bis-Sħana: Saħħan u żomm f'temperatura speċifikata biex tagħti l-proprjetajiet mekkaniċi mixtieqa.

Tkessiħ: Uża l-arja biex tkessaħ b'mod naturali u tistabbilizza l-istruttura.

Irfinar: L-bar tond tal-azzarhuwa aktar soġġett għal ipproċessar fin bħal qtugħ tal-wajer u illustrar biex jinkiseb preċiżjoni u kwalità tal-wiċċ ogħla.

DAQS TAL-PRODOTT

-

Isem tal-Prodott:Bar tal-Azzar

-

Dijametru:2–500 mm

-

Tul:3000–6000 mm

-

Tip:Tond, Kwadru, Eżagonali, Angolu, Bar Ċatt

-

Trattament tal-Wiċċ:Imnaddaf, ibbottiljat, jew miżbugħ skont il-ħtieġa tal-klijent

-

Tolleranza tal-Ħxuna:±0.1 mm

-

Għażliet ta' Materjal:

-

Azzar tal-Karbonju u tal-Liga: 20#–50#, 16Mn–50Mn, 30Mn2–50Mn2, 20Cr, 40Cr, 20CrMnTi, 20CrMo, 15CrMo, 30CrMo, 35CrMo, 42CrMo, 42CrMo4, 60Si2Mn, 65Mn, 27SiMn, 20Mn, 40Mn2, 50Mn

-

Azzar li ma jissaddadx: 1Cr13, 2Cr13, 3Cr13, 4Cr13

-

Azzar Strutturali u tal-Pjanċa: Q195, Q235(A–D,R), Q345(B–D,R), Q345QC, Q345QD, SPCC, SPCD, SPCE, ST37, ST12, ST15, DC01–DC06

-

-

Applikazzjoni:Għodda żgħira, komponenti, wajer tal-ħadid, vireg tal-ġbid, ferrules, assemblaġġi tal-weldjatura, metall strutturali, vireg tal-konnessjoni, ganċi tal-irfigħ, boltijiet, skorfini, magħżel, fusien, gerijiet, roti tal-katina, akkoppjaturi tal-karozzi

-

MOQ:25 tunnellata (ordnijiet ta' kampjuni aċċettati)

-

Ħin tal-Ġarr:15–20 jum tax-xogħol wara d-depożitu jew TT/L/C

-

Ippakkjar għall-Esportazzjoni:Karta reżistenti għall-ilma + ċineg tal-azzar; ippakkjar standard tajjeb għall-baħar; adattat għat-tipi kollha ta' trasport

-

Kapaċità Annwali:250,000 tunnellata/sena

-

Setturi tal-Użu:Bini tal-vapuri, petrokimika, makkinarju, farmaċewtiċi, enerġija u enerġija, kostruzzjoni u dekorazzjoni, enerġija nukleari, aerospazjali, tagħmir marittimu, kimiċi, żebgħa, manifattura tal-karta, fertilizzanti, infrastruttura kostali, ħbula, viti, ġewż, eċċ.

Bar Tond Standard tal-GB

Speċifikazzjonijiet: Q235, Q355, 20, 45, 40Gr

Standard: GB/T 1499.2-2007

GB/T 1499.3-2010

Daqs: 6-12M jew il-ħtieġa tal-klijent

| Daqsijiet tad-Dijametru (mm) | Massa għal kull metru (kg/m | Biċċiet għal kull pakkett | Piż nominali għal kull pakkett ta' 12 metru (tunnellata metrika) |

| 5.5 | 0.187 | 450 | 1.010 |

| 6.0 | 0.222 | 375 | 0.999 |

| 6.5 | 0.260 | 320 | 0.998 |

| 7.0 | 0.302 | 276 | 1.000 |

| 8.0 | 0.395 | 200 | 0.948 |

| 9.0 | 0.499 | 168 | 1.006 |

| 10.0 | 0.617 | 138 | 1.022 |

| 12.0 | 0.888 | 96 | 1.023 |

KARATTERISTIĊI

Vireg tondi tal-azzar irrumblati bis-sħana, dan it-tip ta' azzar tipikament jiġi prodott bl-użu ta' proċess ta' rrumblar bis-sħana, fejn l-azzar l-ewwel jissaħħan 'il fuq mit-temperatura ta' rikristallizzazzjoni tiegħu u mbagħad jiġi rrumblat minn serje ta' rombli biex tinkiseb il-forma mixtieqa. Il-karatteristiċi ewlenin tal-azzar tond irrumblat bis-sħana jinkludu:

-

Saħħa:Vireg tal-azzar tondi rrumblati bis-sħana joffru saħħa u ebusija għolja għal applikazzjonijiet industrijali diversi.

-

Duttilità:Duttilità tajba tippermetti l-iffurmar u l-iffurmar faċli f'diversi prodotti.

-

Irfinar tal-wiċċ:Jista' jkollu wiċċ mhux maħdum jew imqaxxar minn irrumblar bis-sħana, li jista' jiġi llixxat jekk meħtieġ.

-

Versatilità:Użat ħafna fl-industriji tal-kostruzzjoni, tal-manifattura u tal-karozzi għall-affidabbiltà strutturali.

-

Disponibbiltà:Offruti f'daqsijiet u gradi multipli biex jissodisfaw rekwiżiti ta' applikazzjoni differenti.

APPLIKAZZJONI

BiniLiwi tal-ħadid artifiċjali għal djar, skejjel, pontijiet, u toroq.

ManifatturaMakkinarju, tagħmir u produzzjoni ta' partijiet industrijali.

KarozziFusien, xaftijiet u komponenti strutturali tal-karozzi.

Makkinarju tar-RazzettUżat f'makkinarju tal-irziezet għas-saħħa u l-formabbiltà.

Fabbrikazzjoni Ġenerali:Bibien, ċnut, frejms u applikazzjonijiet strutturali oħra.

DIY fil-forma ta' għamara, ornamenti, bini fuq skala żgħira.

Produzzjoni tal-Għodda:Xogħlijiet ta' għodda tal-idejn, għodda tal-magni u makkinarju industrijali.

IPPAKKJAR U TRASPORT

Ippakkjar:

-

Poġġi l-vireg f'munzelli pulit u sikuri; uża ċineg jew ħbula tal-irbit biex tevita li jiċċaqalqu.

-

Kebbeb il-vireg b'materjali li ma jgħaddix ilma minnhom (plastik jew karta li ma tgħaddix ilma minnha) biex tevita s-sadid u l-korrużjoni.

Trasport:

-

Agħżel trasport ibbażat fuq il-kwantità, il-piż, u d-distanza (trakk b'pjattaforma, kontejner, jew vapur).

-

Uża tagħmir ta' rfigħ xieraq (krejnijiet, forklifts, loaders) għal immaniġġjar sikur.

-

Orbot il-merkanzija b'ċineg jew appoġġi biex tevita li tiċċaqlaq waqt it-trasport.

ng: Kebbeb il-vireg tal-azzar b'materjali li ma jgħaddix ilma minnhom (bħal film tal-plastik jew karta li ma tgħaddix ilma minnha) biex tipproteġihom mill-umdità u minn fatturi ambjentali oħra. Dan jgħin biex jipprevjeni s-sadid u l-korrużjoni.

Trasport:

Agħżel il-mod ta' trasport xieraq: Agħżel il-mod ta' trasport xieraq ibbażat fuq il-kwantità u l-piż tal-vireg tal-azzar, bħal trakkijiet b'pjattaforma, kontejners, jew vapuri. Ikkunsidra fatturi bħad-distanza, il-ħin, l-ispiża, u r-regolamenti tat-traffiku.

Uża tagħmir ta' rfigħ adattat: Meta tgħabbi u tħott il-vireg tal-azzar, uża tagħmir ta' rfigħ xieraq, bħal krejnijiet, forklifts, jew loaders. Kun żgur li t-tagħmir għandu kapaċità ta' ġarr ta' tagħbija suffiċjenti biex jimmaniġġja l-vireg tal-azzar b'mod sikur.

Assigura l-merkanzija: Uża ċineg, appoġġi, jew metodi oħra adattati biex twaħħal sew il-vireg tal-azzar ippakkjati mal-vettura tat-trasport, u tevita li jiċċaqalqu, jiżżerżqu, jew jaqgħu waqt it-trasport.

SAĦĦA TAL-KUMPANIJA

Magħmul fiċ-Ċina, servizz tal-ewwel klassi, kwalità avvanzata, magħruf mad-dinja kollha

1. Effett tal-iskala: Il-kumpanija tagħna għandha katina tal-provvista kbira u fabbrika tal-azzar kbira, li tikseb effetti tal-iskala fit-trasport u l-akkwist, u ssir kumpanija tal-azzar li tintegra l-produzzjoni u s-servizzi

2. Diversità tal-prodott: Diversità tal-prodott, kwalunkwe azzar li trid jista' jinxtara mingħandna, prinċipalment involuti fi strutturi tal-azzar, binarji tal-azzar, munzelli tal-folji tal-azzar, parentesi fotovoltajċi, azzar tal-kanali, kolji tal-azzar tas-silikon u prodotti oħra, li jagħmilha aktar flessibbli Agħżel it-tip ta' prodott mixtieq biex tissodisfa bżonnijiet differenti.

3. Provvista stabbli: Li jkollok linja ta' produzzjoni u katina tal-provvista aktar stabbli tista' tipprovdi provvista aktar affidabbli. Dan huwa speċjalment importanti għax-xerrejja li jeħtieġu kwantitajiet kbar ta' azzar.

4. Influwenza tal-marka: Ikollu influwenza ogħla tal-marka u suq akbar

5. Servizz: Kumpanija kbira tal-azzar li tintegra l-adattament, it-trasport u l-produzzjoni

6. Kompetittività tal-prezzijiet: prezz raġonevoli

*Ibgħat l-email lil[email protett]biex tikseb kwotazzjoni għall-proġetti tiegħek

IŻ-ŻJARA TAL-KLIJENTI

Mistoqsijiet Frekwenti

1. Kif nista' nikseb kwotazzjoni?

Ħallilna messaġġ u aħna nirrispondulek minnufih.

2. Se twassal fil-ħin?

Iva, aħna niggarantixxu prodotti ta' kwalità u kunsinna f'waqtha. L-onestà hija l-prinċipju tagħna.

3. Nista' nikseb kampjuni qabel ma nordna?

Iva, il-kampjuni ġeneralment ikunu bla ħlas u jistgħu jsiru mill-kampjun jew mit-tpinġija teknika tiegħek.

4. X'inhuma t-termini tal-ħlas tiegħek?

Termini standard: depożitu ta' 30%, bilanċ kontra B/L. EXW, FOB, CFR, CIF disponibbli.

5. Taċċetta spezzjoni minn partijiet terzi?

Iva, l-ispezzjoni minn parti terza hija milqugħa.

6. Kif nistgħu nafdaw il-kumpanija tiegħek?

Għandna snin ta' esperjenza bħala Fornitur tad-Deheb, bil-kwartieri ġenerali tagħna f'Tianjin, u nilqgħu l-verifika bi kwalunkwe metodu.