Ferrovija tal-Azzar Standard DIN Ferrovija tal-Azzar tal-Karbonju Standard

materjal tal-binarjihija parti essenzjali u importanti fil-kostruzzjoni u t-tħaddim tal-ferrovija. Fit-trasport ferrovjarju, il-ferrovija hija responsabbli biex issostni u ġġorr il-piż kollu tal-ferrovija, u l-kwalità u l-prestazzjoni tagħha jaffettwaw direttament is-sigurtà u l-istabbiltà tal-ferrovija. Għalhekk, il-ferrovija għandu jkollha saħħa għolja, reżistenza għall-użu, reżistenza għall-korrużjoni u proprjetajiet fiżiċi u kimiċi eċċellenti oħra.

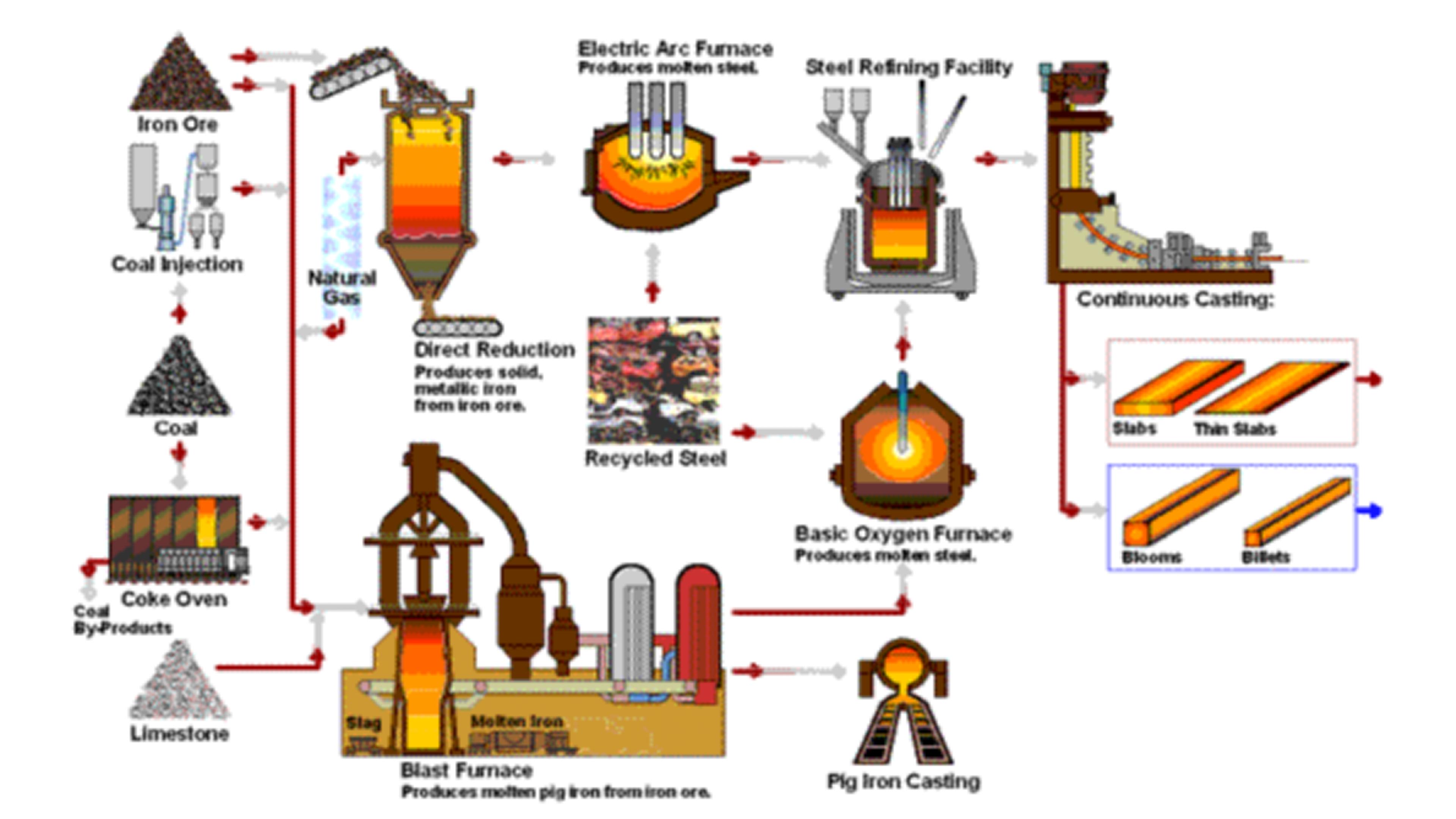

PROĊESS TA' PRODUZZJONI TAL-PRODOTT

Teknoloġija u Proċess ta' Kostruzzjoni

Il-proċess tal-kostruzzjonibinarji tal-azzarIl-bini tal-binarji jinvolvi inġinerija ta’ preċiżjoni u konsiderazzjoni bir-reqqa ta’ diversi fatturi. Jibda bid-disinn tat-tqassim tal-binarji, filwaqt li jitqies l-użu maħsub, il-veloċitajiet tal-ferrovija, u t-terren. Ladarba d-disinn jiġi ffinalizzat, il-proċess tal-kostruzzjoni jibda bil-passi ewlenin li ġejjin:

1. Skavar u Pedament: L-ekwipaġġ tal-kostruzzjoni jħejji l-art billi jħaffer iż-żona u joħloq pedament b'saħħtu biex isostni l-piż u l-istress imposti mill-ferroviji.

2. Installazzjoni tal-Ballast: Saff ta’ ġebel imfarrak, magħruf bħala ballast, jitqiegħed fuq il-wiċċ ippreparat. Dan iservi bħala saff li jassorbi x-xokkijiet, jipprovdi stabbiltà, u jgħin biex it-tagħbija titqassam b’mod uniformi.

3. Irbit u Twaħħil: Imbagħad jiġu installati rabtiet tal-injam jew tal-konkrit fuq il-ballast, li jimitaw struttura bħal qafas. Dawn ir-rabtiet joffru bażi sigura għall-linji tal-ferrovija tal-azzar. Jiġu mwaħħla bl-użu ta' spikes jew klipps speċifiċi, u jiżguraw li jibqgħu f'posthom sew.

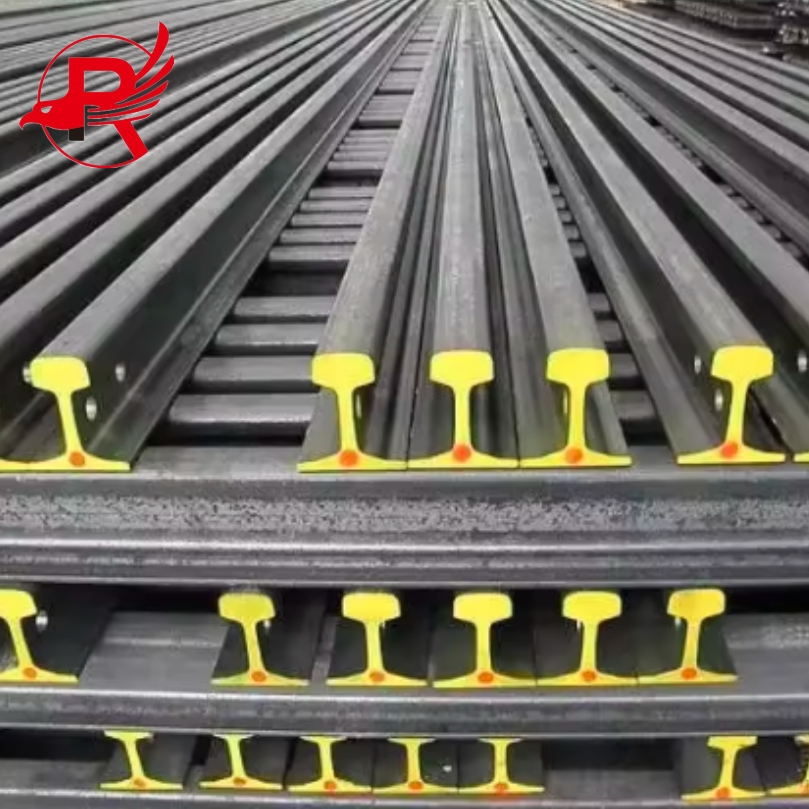

4. Installazzjoni tal-Binarji: Il-binarji tal-ferrovija tal-azzar ta' 10m, spiss imsejħa binarji standard, huma mqiegħda bir-reqqa fuq it-travi. Billi huma magħmula minn azzar ta' kwalità għolja, dawn il-binarji għandhom saħħa u durabilità notevoli.

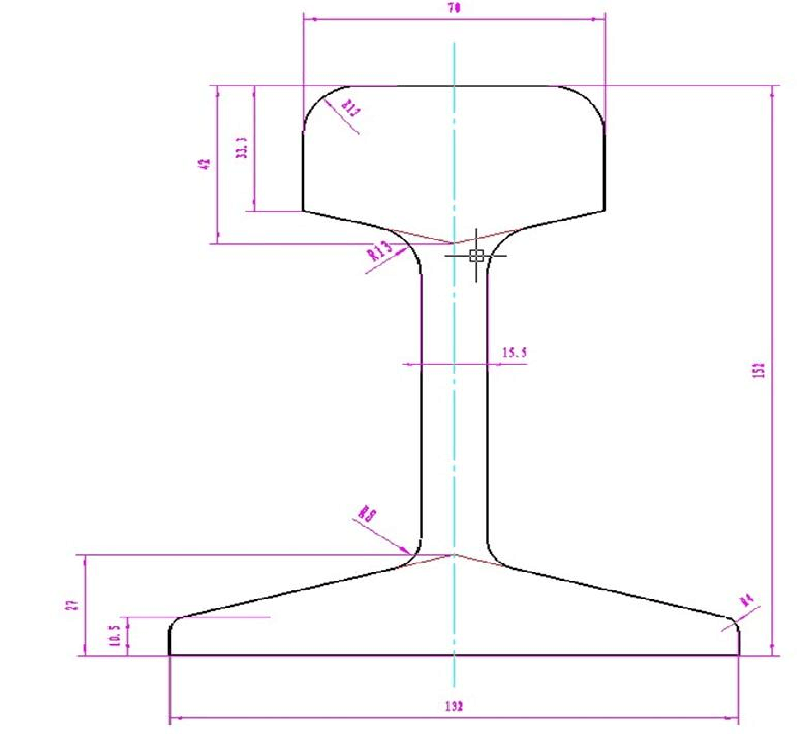

DAQS TAL-PRODOTT

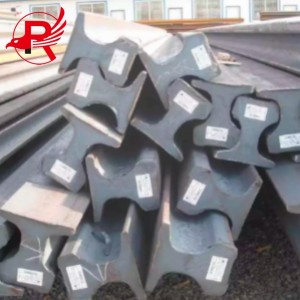

Ferrovija tal-azzar standard DIN

| mudell | Wisa' tar-ras K (mm) | Għoli tal-binarju H1 (mm) | Wisa' tal-qiegħ B1 (mm) | Piż f'metri (kg/m) |

| A45 | 45 | 55 | 125 | 22.1 |

| A55 | 55 | 65 | 150 | 31.8 |

| A65 | 65 | 75 | 175 | 43.1 |

| A75 | 75 | 85 | 200 | 56.2 |

| A100 | 100 | 95 | 200 | 74.3 |

| A120 | 120 | 105 | 220 | 100.0 |

| A150 | 150 | 150 | 220 | 150.3 |

| MRS86 | 102 | 102 | 165 | 85.5 |

| MRS87A | 101.6 | 152.4 | 152.4 | 86.8 |

Ferrovija tal-azzar standard DIN:

Speċifikazzjonijiet: A55, A65, A75, A100, A120, S10, S14, S18, S20, S30, S33, S41R10, S41R14, S49

Standard: DIN536 DIN5901-1955

Materjal: ASSZ-1/U75V/U71Mn/1100/900A/700

Tul: 8-25m

VANTAĠĠ

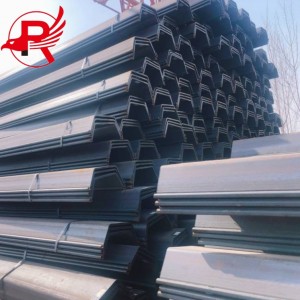

1. Materjali eċċellenti:poġġaman tal-azzarHuma magħmula minn azzar eċċellenti u jgħaddu minn proċessi stretti ta' tidwib, irrumblar u trattament bis-sħana biex jiżguraw li jkollhom proprjetajiet mekkaniċi eċċellenti u reżistenza għall-korrużjoni. Dan jippermetti lill-linji ferrovjarji standard Ġermaniżi jżommu prestazzjoni stabbli u jestendu l-ħajja tas-servizz tagħhom meta jifilħu l-pressjoni enormi ġġenerata waqt it-tħaddim tal-ferrovija.

2. Dimensjonijiet u tolleranzi preċiżi: Il-produzzjoni tal-linji ferrovjarji standard Ġermaniżi ssegwi standards industrijali Ġermaniżi stretti, b'tolleranzi dimensjonali żgħar u installazzjoni faċli. Id-dimensjonijiet preċiżi jiżguraw kuntatt tajjeb bejn il-linji ferrovjarji u r-roti, inaqqsu l-użu u l-istorbju, u jtejbu l-intoppi u l-kumdità tal-ferrovija.

3. Saħħa għolja u reżistenza għall-użu: Il-binarji standard Ġermaniżi għandhom saħħa għolja ta' rendiment u saħħa tat-tensjoni u jistgħu jifilħu l-impatt u l-vibrazzjoni tat-tħaddim tal-ferrovija. Fl-istess ħin, il-wiċċ tagħhom ġie ttrattat b'mod speċjali biex ikollu reżistenza tajba għall-użu u jnaqqas l-ispejjeż tal-manutenzjoni.

4. Reżistenza tajba għall-għeja: Il-binarji standard Ġermaniżi jadottaw proċess ta' rrumblar matur u teknoloġija ta' trattament bis-sħana biex jagħtuhom reżistenza tajba għall-għeja. Anke f'ambjenti tax-xogħol ħorox, jistgħu jżommu prestazzjoni stabbli u jnaqqsu l-inċidenza ta' ħsarat u inċidenti.

5. Firxa wiesgħa ta' applikazzjonijiet: Il-linji ferrovjarji standard Ġermaniżi huma adattati għal diversi sistemi ta' transitu ferrovjarju, inklużi ferroviji, subways, linji ferrovjarji ħfief, eċċ. Il-prestazzjoni eċċellenti u l-firxa wiesgħa ta' applikazzjonijiet tagħhom jagħmlu l-linji ferrovjarji standard Ġermaniżi wieħed mill-prodotti fil-qasam globali tat-transitu ferrovjarju.

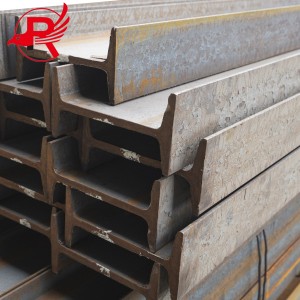

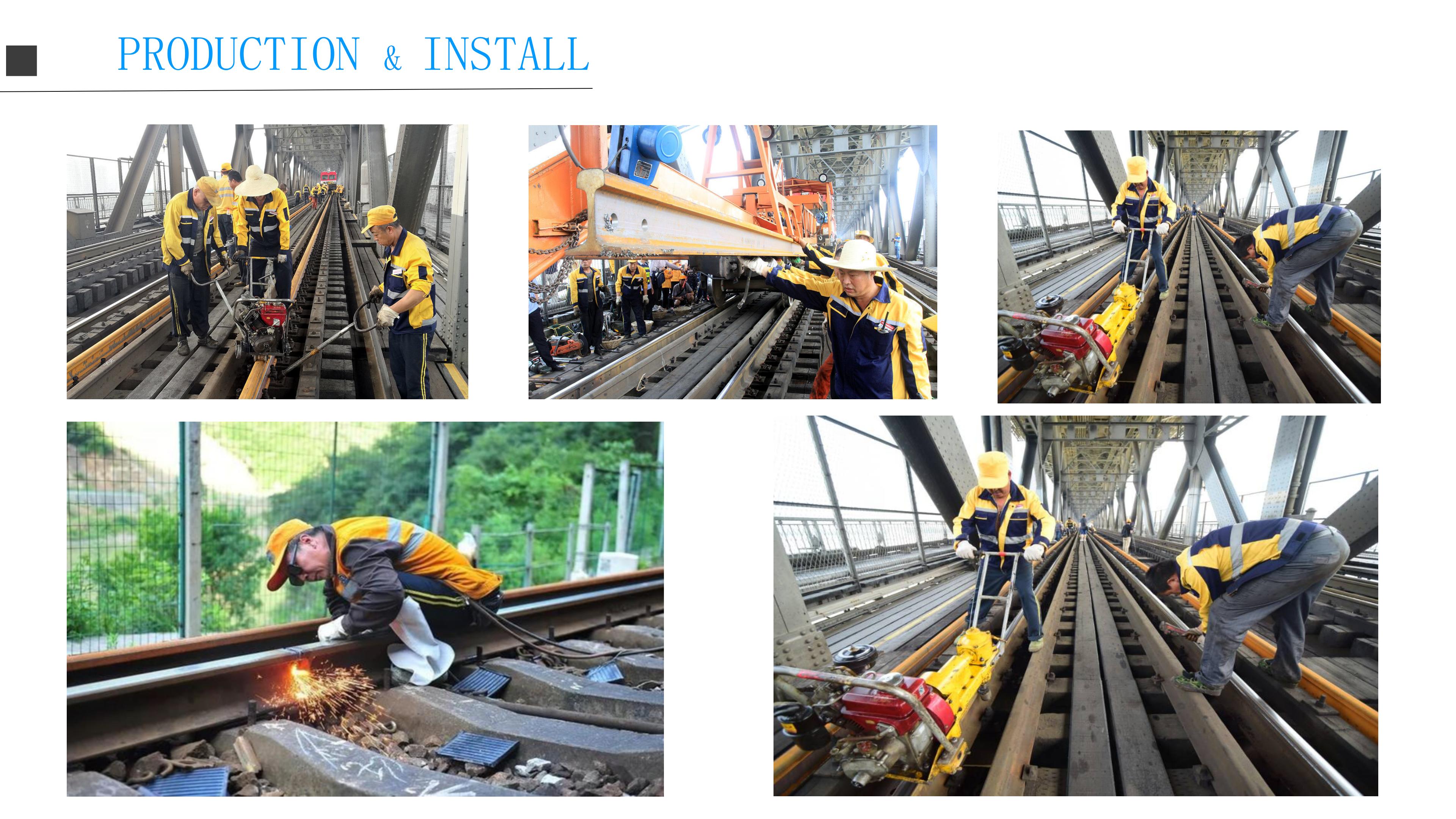

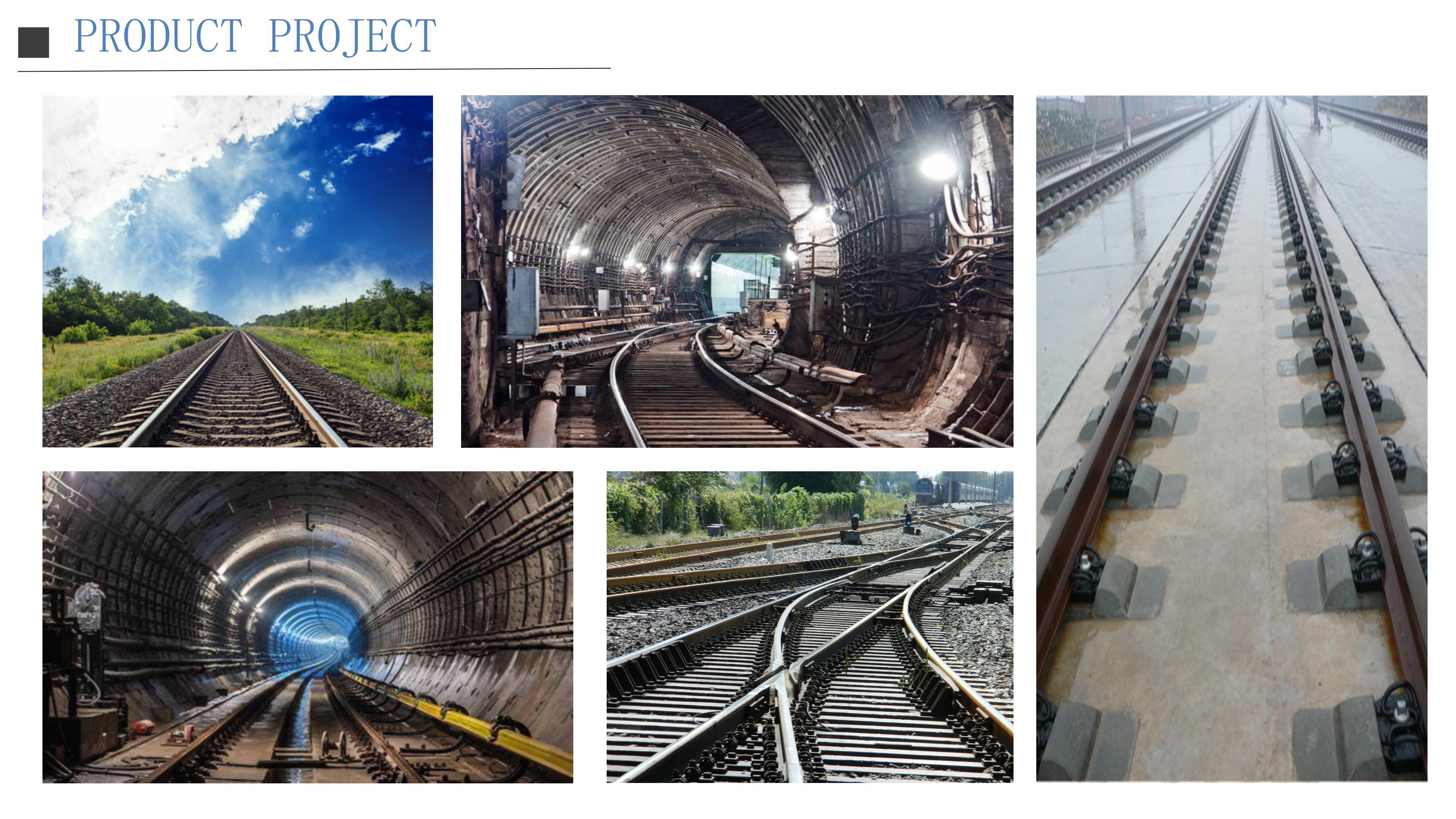

PROĠETT

Il-kumpanija tagħna'13,800 tunnellata ta'azzar tal-ferrovijaesportati lejn l-Istati Uniti ġew mibgħuta fil-Port ta' Tianjin f'daqqa. Il-proġett ta' kostruzzjoni tlesta bl-aħħar binarju jitqiegħed b'mod kostanti fuq il-linja ferrovjarja. Dawn il-binarji huma kollha mil-linja ta' produzzjoni universali tal-fabbrika tagħna tal-binarji u r-raġġi tal-azzar, bl-użu ta' prodotti globali skont l-ogħla u l-aktar standards tekniċi rigorużi.

Għal aktar informazzjoni dwar prodotti ferrovjarji, jekk jogħġbok ikkuntattjana!

WeChat: +86 13652091506

Tel: +86 13652091506

Email:[email protett]

APPLIKAZZJONI

1. Trasport bil-ferrovija

Il-binarji standard Ġermaniżi jintużaw ħafna fil-qasam tat-trasport ferrovjarju. Bħala materjal tal-binarji b'saħħa għolja, reżistenza għolja għall-użu u stabbiltà għolja, il-binarji standard Ġermaniżi jistgħu jipprovdu ambjent operattiv sikur, stabbli u eċċellenti għat-trasport ferrovjarju. F'diversi sistemi ferrovjarji bħal ferroviji ta' veloċità għolja, transitu ferrovjarju urban u ferroviji ta' trasport tqil, il-binarji standard Ġermaniżi għandhom rwol importanti.

2. Kostruzzjoni tal-inġinerija

Il-binarji standard Ġermaniżi jintużaw ħafna wkoll fil-qasam tal-inġinerija u l-kostruzzjoni. Minħabba s-saħħa għolja u l-kapaċità tajba li jifilħu t-tagħbija tagħhom, il-binarji standard Ġermaniżi spiss jintużaw fil-kostruzzjoni ta' proġetti kbar ta' inġinerija bħal pontijiet, mini u awtostradi. Jistgħu jtejbu l-istabbiltà u s-sigurtà tal-istrutturi tal-inġinerija, inaqqsu r-riskji tal-inġinerija, u jtejbu l-kwalità tal-inġinerija.

3. Minjieri Minjieri

Fil-qasam tal-minjieri u l-minjieri, il-linji ferrovjarji standard Ġermaniżi wkoll għandhom prestazzjoni tajba. Minħabba l-ambjent ħarxa tal-minjieri u r-rekwiżiti għoljin għall-materjali tal-binarji, il-linji ferrovjarji standard Ġermaniżi tal-azzar rebħu l-favur tal-industrija tal-minjieri bil-prestazzjoni eċċellenti u d-durabbiltà tagħhom. Jistgħu jifilħu t-tagħbija tqila u l-impatt tal-minjiera, jiżguraw it-tħaddim normali tat-trakkijiet tal-minjieri u t-tagħmir tat-trasport, u jtejbu l-effiċjenza u s-sigurtà tal-minjieri.

4. Binarju tal-makkinarju agrikolu

Fil-qasam tal-binarji tal-makkinarju agrikolu, il-binarji tal-azzar standard Ġermaniżi għandhom ukoll rwol importanti. Il-makkinarju agrikolu jeħtieġ li jaħdem f'diversi terreni u ambjenti kumplessi, u għandu rekwiżiti għoljin għall-materjali tal-binarji. Bis-saħħa għolja, ir-reżistenza għolja għall-użu u l-istabbiltà għolja tiegħu, il-binarji standard Ġermaniżi jipprovdu bażi stabbli għat-tħaddim tal-makkinarju agrikolu u jtejbu l-effiċjenza u s-sikurezza tal-produzzjoni agrikola.

5. Binarji ta' tagħmir ta' makkinarju tqil

Fil-qasam tal-binarji tat-tagħmir u l-makkinarju tqil, il-binarji standard Ġermaniżi għandhom ukoll vantaġġi sinifikanti. Il-makkinarju u t-tagħmir tqil jeħtieġ li jifilħu tagħbijiet u forzi ta' impatt enormi, u għandhom rekwiżiti ogħla għall-materjali tal-binarji. Il-binarji standard Ġermaniżi, bis-saħħa għolja tagħhom, ir-reżistenza għolja għall-użu u l-istabbiltà għolja, jiżguraw it-tħaddim normali tal-makkinarju u t-tagħmir tqil u jtejbu l-effiċjenza u s-sikurezza tal-produzzjoni.

IPPAKKJAR U TRASPORT

1. Trasport bil-ferrovija

Il-binarji twal huma waħda mill-oġġetti użati b'mod komuni fit-trasport ferrovjarju. It-trasport ferrovjarju għandu l-vantaġġi tas-sigurtà, il-veloċità u l-ispiża baxxa. Matul it-trasport, għandha tingħata attenzjoni lill-protezzjoni tal-binarji mill-ħsara, u ġeneralment jintużaw vetturi speċjali għat-trasport ferrovjarju. Matul il-proċess ta' installazzjoni, għandha tingħata attenzjoni lid-direzzjoni tat-tqegħid u l-metodi ta' konnessjoni biex jiġu evitati żbalji kkawżati minn fatturi umani.

2. Trasport bit-triq

It-trasport bit-triq huwa metodu komuni ieħor ta' trasport ta' linji ferrovjarji twal u huwa wkoll wieħed mill-metodi komuni meta jinbnew jew jissewwew linji ferrovjarji. Matul it-trasport, iridu jittieħdu ċerti miżuri biex jiġi żgurat li l-oġġetti ma jiżolqux jew jitbandlux, u b'hekk jiġu evitati inċidenti. Fl-istess ħin, għandu jiġi fformulat ukoll pjan dettaljat tat-trasport u jitħaddem skont il-pjan.

3. Trasport bl-ilma

Għat-trasport ta' linji ferrovjarji twal fuq distanzi twal, ġeneralment jintuża t-trasport bl-ilma. Fit-trasport bl-ilma, jistgħu jintgħażlu varjetà ta' vapuri għat-trasport, bħal vapuri tal-merkanzija, barkuni, eċċ. Qabel ma titgħabba l-merkanzija, jeħtieġ li jiġu kkunsidrati t-tul u l-piż tal-linji ferrovjarji, kif ukoll il-kapaċità li jġorru t-tagħbija u l-prestazzjoni tas-sikurezza tal-vapur biex jiġi ddeterminat il-metodu u l-kwantità tat-tagħbija xierqa. Barra minn hekk, jeħtieġ li jittieħdu miżuri protettivi biex tiġi evitata ħsara aċċidentali lill-linji ferrovjarji waqt it-trasport bl-ilma.

It-trasport ta' binarji twal huwa kwistjoni ta' inġinerija importanti ħafna, u jeħtieġ li tingħata attenzjoni lil serje ta' speċifikazzjonijiet operattivi u dettalji ta' protezzjoni biex jiġu evitati konsegwenzi ħżiena bħal telf u diżgrazzji minħabba negliġenza.

SAĦĦA TAL-KUMPANIJA

Il-kumpanija tagħna'Fl-istess ħin, 13,800 tunnellata ta’ linji tal-azzar esportati lejn l-Istati Uniti ġew trasportati fil-Port ta’ Tianjin. Il-proġett ta’ kostruzzjoni tlesta bl-aħħar linja ferrovjarja titqiegħed b’mod kostanti fuq il-linja ferrovjarja. Dawn il-linji kollha huma mil-linja ta’ produzzjoni universali tal-fabbrika tagħna tal-linji tal-ferrovija u t-travi tal-azzar, bl-użu ta’ prodotti globali skont l-ogħla u l-aktar standards tekniċi rigorużi.

Għal aktar informazzjoni dwar prodotti ferrovjarji, jekk jogħġbok ikkuntattjana!

WeChat: +86 13652091506

Tel: +86 13652091506

Email:[email protett]

IŻ-ŻJARA TAL-KLIJENTI

Mistoqsijiet Frekwenti

1. Kif nista' nikseb kwotazzjoni mingħandek?

Tista' tħallilna messaġġ, u aħna nwieġbu kull messaġġ fil-ħin.

2. Se twassal il-merkanzija fil-ħin?

Iva, aħna nwiegħdu li nipprovdu prodotti tal-aqwa kwalità u kunsinna fil-ħin. L-onestà hija l-prinċipju tal-kumpanija tagħna.

3. Nista' nikseb kampjuni qabel l-ordni?

Iva, ovvjament. Normalment il-kampjuni tagħna huma bla ħlas, nistgħu nipproduċuhom permezz tal-kampjuni jew it-tpinġijiet tekniċi tiegħek.

4. X'inhuma t-termini tal-ħlas tiegħek?

It-terminu tas-soltu tal-ħlas tagħna huwa depożitu ta' 30%, u l-mistrieħ kontra B/L. EXW, FOB, CFR, CIF.

5. Taċċetta l-ispezzjoni minn parti terza?

Iva assolutament naċċettaw.

6. Kif nafdaw il-kumpanija tiegħek?

Aħna speċjalizzati fin-negozju tal-azzar għal snin bħala fornitur tad-deheb, il-kwartieri ġenerali tagħna jinsabu fil-provinċja ta' Tianjin, merħba biex ninvestigaw bi kwalunkwe mod, bil-mezzi kollha.